Originally published in Points West magazine

Summer 1997

The Arms and Art of the Remington Arms Company

By Howard Michael Madaus

Former Curator, Cody Firearms Museum, Robert W. Woodruff Firearms Chair

In 1816, the 22-year-old blacksmith Eliphalet Remington forged his first gun barrel. The process was slow and tedious. A skelp of iron (a rectangular piece of raw cast iron about two inches square across its center and varying in length from one to two feet) was heated in a forge until cherry red, and then brought to an anvil where it was gradually stretched by repeated blows around (called a mandrill) until it completely encircled the rod. The seam was then welded shut.

The rough barrel was then straightened, the interior (bore) polished smooth, and the exterior filed to the desired size and configuration. The bore was then rifled—cut with separated parallel grooves that twisted through the length of the barrel. The breech (rear) end of the barrel was then threaded for about half inch and a separate plug was forged, formed, threaded, and fitted to the breech, and front and rear sights, completed the product. For the next 30 years, Eliphalet Remington would specialize in producing such barrels for the burgeoning gun-making trade that served the growing population along the commerce routes adjoining the Erie Canal and Mohawk Valley. By 1845 Remington was the preeminent barrel supplier not only to the upstate New York gun trade, but also throughout the expanding Midwest.

In 1846, war broke out between the United States and Mexico. In need of additional arms for the militia and newly organized volunteers, the U.S. government had let out contracts to several private arms makers. Eliphalet Remington secured two of these contracts after the original contractors either defaulted on their agreements or subcontracted the work to Remington. As a result, between 1847 and 1851, Remington delivered to the United States government 6,000 longarms; 5,000 rifles for the Army and 1,000 carbines for the Navy. These were the first complete arms made by Remington and would mark Remington’s full entry into the arms trade, a business that would continue for 150 years until today.

After several other government contracts for additional longarms, Eliphalet Remington (now joined in his business by his sons) would venture into the lucrative revolver trade, basing his early production on the patents of Fordyce Beals. With the outbreak of the American Civil War, Remington & Sons would expand their production facilities dramatically. In addition to 40,000 rifle muskets, 10,000 rifles, and several thousand carbines, Remington would manufacture in excess of 150,000 revolvers for military service during the war. These revolvers continued to serve as sidearms in the period of western expansion that followed the Civil War.

“It Never Failed Me” traced the history of Remington’s production through twenty phases of their product line. The first displays traced the evolution of Remington as a barrel maker, the company’s early military contracts, early ventures in the revolver trade, and its expansion during the Civil War. The next sections of the exhibit traced the history of E. Remington & Sons during the two decades that followed the American Civil War.

During this period Remington led the field in the new technology of self-contained metallic cartridges, adapting its entire revolver line to the system and adopting Joseph Rider’s patented breechloading mechanism to a line of military and civilian single-shot rifles. Later the breechloading system of Lewis L. Hepburn was added to the line to create a new breed of high quality target rifles. In the decade after the Civil War Remington introduced several small pocket pistols (“derringers”) for the urban market and a single action .45 and .44-40 caliber revolver to compete against Colt’s famous “Single Action Army” and “Frontier” revolvers for the western market.

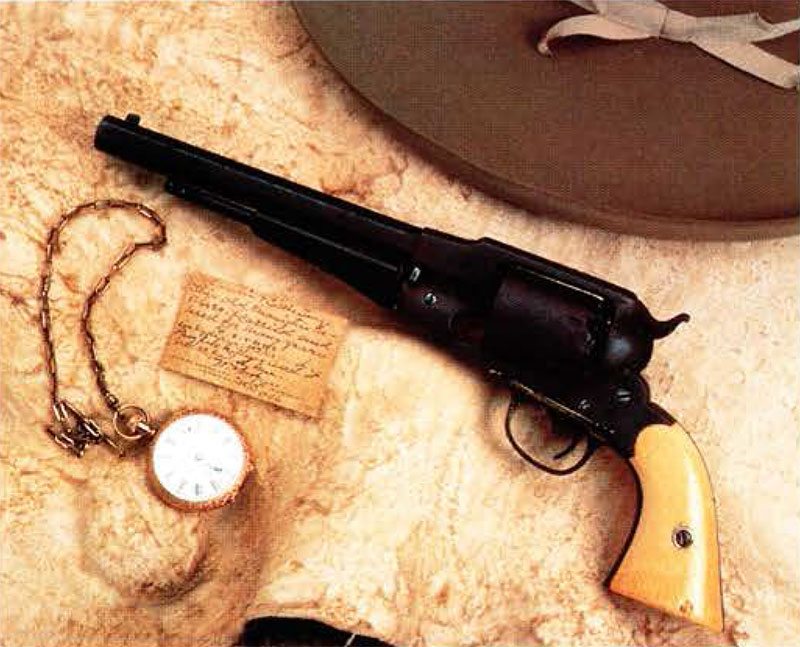

Indeed, a Remington “New Model” Army revolver would be William F. “Buffalo Bill” Cody’s handgun of choice during his career as buffalo hunter and Army scout on the frontier. Years later, Cody presented that revolver to the foreman of his Nebraska ranch, Charlie Trego. Included with the gift was his business card bearing the note “It Never Failed Me.” Buffalo Bill’s comment would provide the title for the retrospective exhibit detailing the history of the Remington Arms Company’s 180 years of arms production. This exhibit open[ed] to the public on May 17, 1997, in the Center’s Special Exhibition Gallery and [closed] September 28, 1997.

E. Remington & Sons revolvers never successfully dented Colt’s dominance of the western revolver market. Similarly, the adoption of Keene’s tubular magazine and James Paris Lee’s box magazine bolt action repeating rifles never had a significant impact on Winchester’s dominance of the repeating rifle market. Despite Remington’s failure to gain a lasting foothold in these two markets, the Rider patent and Samuel Remington’s shrewd marketing skills in foreign sales kept E. Remington & Sons competitive until the mid-1880s. With the decline in foreign martial sales following Samuel Remington’s death, the company’s fortune dropped precipitously in 1888, to save the remnants, the firm went into receivership with control shared by Winchester’s vice president, William Bennett and Marcellus Hartley, owner of the Union Metallic Cartridge Company, the nation’s prime manufacturer of ammunition. Renamed the Remington Arms Company in 1888, under Hartley’s control, Remington was reborn. A shotgun line introduced in 1874 was significantly improved in 1889 and became a major source of company income during Hartley’s regime.

After Hartley’s death in 1902, control of the company fell to his grandson, Marcellus Hartley Dodge. All aspects of Remington’s production during the first half of the 20th century are treated in separate cases. The cases that form the third major section of the exhibit trace Dodge’s aegis of the company (for a while known as Remington Arms/UMC). Among the cases are those devoted to Remington’s production of semi-automatic shotguns, rifles, and pistols, cases emphasizing Remington’s slide action repeating shotguns and rifles, and cases displaying Remington’s small bore bolt action rifles. It was during this same period that Remington expanded its production to become an “arsenal for democracy” for the U.S. and its allies during both World War I and World War II.

The final section of the exhibit treats Remington’s experiments with new materials and products in the period following the company’s sesquicentennial in 1966. The final cases depict current products made by Remington Arms Company, Incorporated, since its 1994 separation from Dupont (which had assumed financial control of Remington during the depths of the Depression).

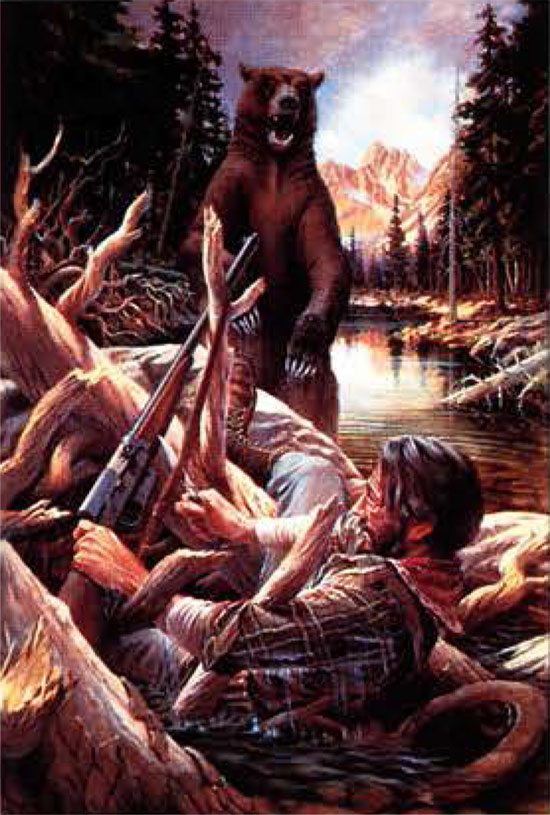

The exhibit It Never Failed Me contained more than 725 Remington firearms, each one of them distinct in some respect. The vast majority (all but about fifty on loan from the Remington Arms Company) were provided specifically for this exhibit by 80 members of the Remington Society of America, an organization founded in 1981 to promote the collection of historical Remington products. The Society now numbers about 650 members. In addition to the arms loaned by the Remington Society of America and the Remington Arms Company, the latter also loaned ninety-two paintings that form part of the original advertising and calendar art of the company’s collection. These paintings, representing several of the better-known artists of the first decades of this century (including N.C. Wyeth, Philip R. Goodwin, and Frank Leyendecker), as well as Remington’s more recently commissioned calendar and poster artists (Richard Kuhn, Tom Beecham, and L.W. Duke) were integrated throughout the exhibit to provide color and historical perspective to the arms depicted.

The Buffalo Bill Historical Center was the sole venue for this important exhibit of America’s oldest continuous arms maker. It is unlikely that the assemblage of arms on loan will ever be united again. To commemorate the exhibit, a full-color catalogue depicting every arm displayed is under preparation and will be available by mid-June to complement the exhibit.

Post 042