Mechanical Musings at the Museum

A building engineer coming into the Center of the West would see very little by way of mechanical equipment that he wouldn’t recognize. True, there are some aspects of this facility that are unusual; because it was built over the course of more than forty years, there are multiple “compartments,” if you will, to the mechanical systems, which tend to reflect the design preferences of the period they were constructed. To some degree we have here a living museum of air conditioning design. I would venture to say our visitors, and even our employees, don’t care much about that.

If I try to describe to most folks the contrast between, say, a multizone air handler and a variable volume fan, eyes tend to glaze over and heads begin to bob in the universal body language that says “I’m pretending to listen but this is really boring!” By and large, the fans turn, the pumps run, the boilers make hot water and the chiller makes cold. The climate control system really only gets public notice when one or more of these things isn’t happening as it should.

To put some interest into the story of this equipment, I sometimes like to make meaningless comparisons to things people can relate to… Today, dear reader, is your lucky day!

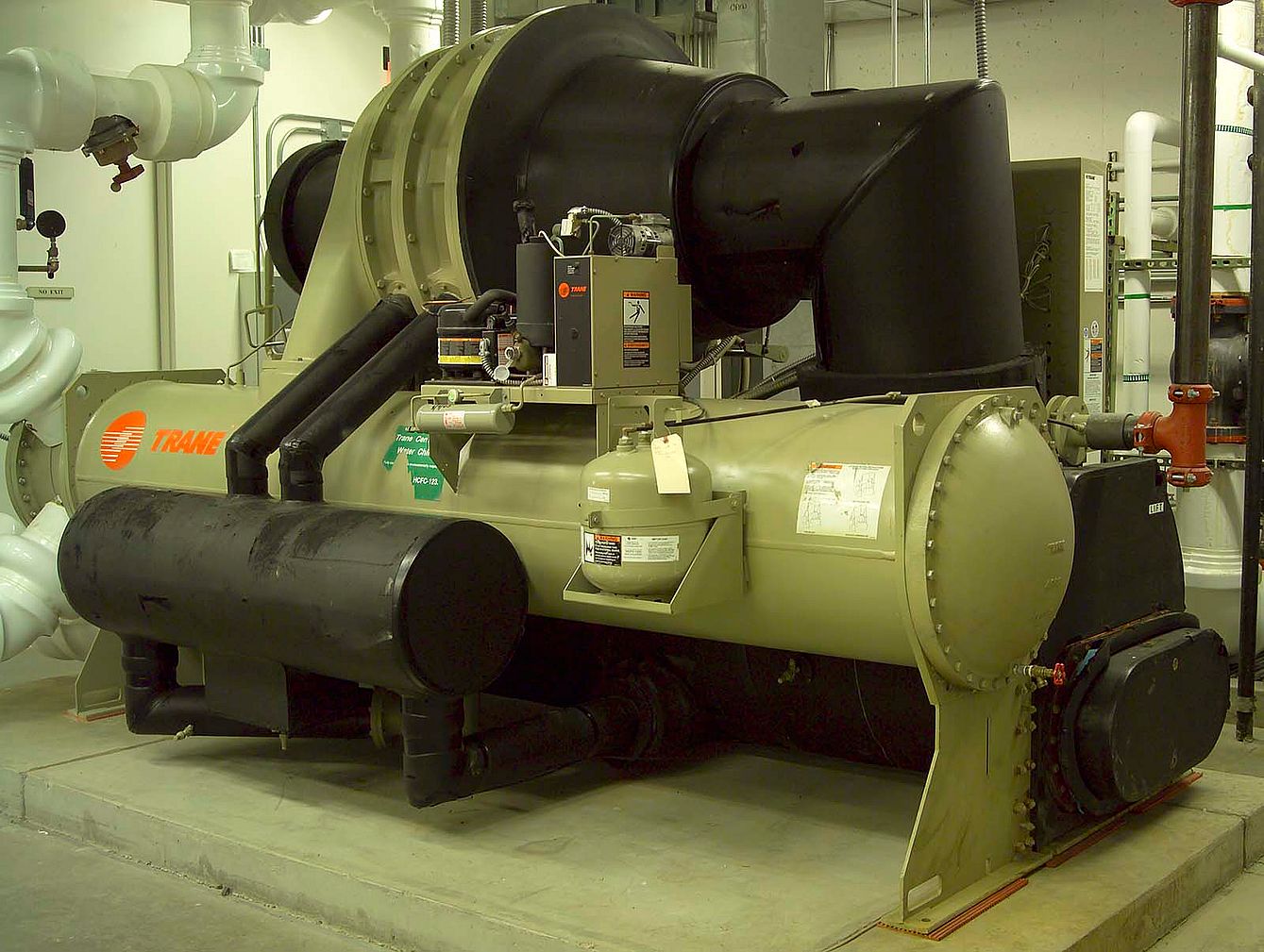

The Facilities chiller was commissioned in May 2001. By and large, it has run well and dependably since then, and before this cooling season is over it will have clocked over 30,000 hours of run time. This means, if it were an automobile travelling at 65 miles per hour, it would have gone almost two million miles (1.95 million) or four round trips to the moon! But of course, although it sings to me on summer days, the chiller can’t really fly…

We have a number of pumps in the building. A precise estimate of the volume of water we move with these pumps is difficult—there are so many variables. Having said that, let me just throw some crazy numbers at you. Estimating the run time of our main pumps (both heating and cooling) and using nameplate flow ratings, I can tell you that we move approximately 804 million gallons of water annually through said pumps (of course these are mostly closed loop systems so it’s really just the same 7,000 gallons going round and round). And that sounds like a lot, except that if we were to attempt to pump out the Buffalo Bill Reservoir at that rate, it would take almost 34 years! And of course water is always flowing into the reservoir so we could never really pump it out… Don’t worry, irrigators! Your water is safe from me!

The Plains Indian Museum steam boiler, which provides humidification for the Plains Indian Museum during the winter, uses approximately five thousand gallons of purified water a month during the winter. This water does not get recirculated, except in a planetary sense. If I used that boiler to make espresso instead of moist air, I could make 320,000 shots in a month. The boiler could do it, but I’m not sure there’s enough time in the day for me to make that much coffee! How many pounds of beans would that be?

Now, if you’re an astrophysicist, a hydrological engineer, or a barista, you may be inclined to find technical flaws in my reasoning or arithmetic. Please—rather than point out my errors, I encourage you to find in your own professions a way of looking at things that captures the imaginations of the uninitiated.

Written By

Phil Anthony

Phil Anthony is the Operating Engineer at the Buffalo Bill Center of the West. He has been in the HVAC-R service industry for over 30 years (fifteen of them at the Center.) Phil holds journeyman certificates through the City and County of Denver as a steamfitter and a refrigeration technician, and a low-voltage electrical technician’s license with the state of Wyoming. An artist, poet, musician (sort of,) and avid outdoorsman, Phil has been called "a true renaissance man."